- Forged 6061-T6 Hard Anodised Aluminium Front Upper Mounts - Strong and Lightweight, our Forged Upper Mounts are Hard Anodised for superior Corrosion Resistance

- Forged 6061-T6 Hard Anodised Aluminium Rear Upper Mounts (Where Applicable) - Strong and Lightweight, our Forged Upper Mounts are Hard Anodised for superior Corrosion Resistance

- High-Tensile Carbon Steel Front Camber Plate with Anti-Slip Coating - CNC-Machined High-Tensile Carbon Steel supports more load than lesser-quality mounts

- Camber Angles can be adjusted precisely to your driving needs (MacPherson)

- Oversized PTFE-Lined Japanese Spherical Upper Mount Bushing - Increases shock articulation and prevents coil-bowing

- Higher load rating for increased durability

- Minimises knocking noise associated with lesser-quality bearings

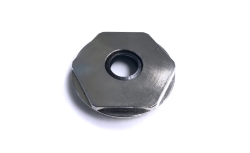

- Forged 6061-T6 Hard Anodised Aluminium Upper Spring Perch with Sealed OEM-Style Thrust Bearing - Strong and Lightweight, our Forged Upper Spring Perches are Hard Anodised for superior Corrosion Resistance

- High Quality Sealed OEM-Style Thrust Bearing removes rotational stress from the upper mount and is sealed from the elements

- Unlike our competitors that use regular Radial Ball Bearings, our Thrust Bearings rotate in parallel to the upper mount and will not cause catastrophic chassis damage should it fail

- 65mm ID Cold-Wound Japanese HS5.TW Steel Linear Springs from SWIFT - Made in Japan by Tohatsu Spring Company, SWIFT Springs are made from the highest quality Japanese-grade spring steel, using proprietary manufacturing processes. These are the #1 Performance Coilover Spring on the market, providing an industry leading +/- 3% deviance from rated load over the entire stroke, and are backed by SWIFT's Lifetime Warranty against Spring Sag

- Not all springs are manufactured the same. Lesser-quality, Taiwanese-manufactured springs offer inferior performance and durability

- Although more expensive, we believe the increase in performance more than offsets the marginal increase in manufacturing costs

- OEM-Balanced Spring Rates - The majority of budget coilovers currently on the market offer default spring rates that deviate from the oem-balanced spring rates

- By not accounting for Motion Ratio Calculations and just replicating race-car setups, this results in a very unbalanced and uncomfortable ride on a Street Car

- 52mm OD Cold-Drawn Japanese SAE 1020 Seamless Carbon Steel Shock Body - Offers superior physical properties and strength-to-weight ratio over lesser manufacturing processes

- Black-Zinc Plated Fully-Threaded Shock Body with 250hrs of Salt-Spray Testing - Offers superior corrosion-resistance

- Forged SAE 4140 Chromoly Steel Piston Rod - Monotube shocks, although offering increased performance over Twintube shocks, have an inherent weakness; a load-bearing Piston Rod

- Our over-engineered solution to the problem, with only a marginal increase in manufacturing costs, is our proprietary Chromoly Steel Piston Rod. We are the only company to manufacture this type of Piston Rod, and is currently used by several high-end European brands under a "transfer-of-technology" agreement

- Offering a substantial increase in tensile strength over lesser-quality rods, not only does this keep costs down, it significantly increases product safety

- 4mm Rebound Adjustment - Our Coilovers allow up to 4mm of Rebound Bleed Adjustment, allowing you to fine-tune your vehicle comfort and handling

- Proprietary Bleed Needles and Jet Valves from the USA are used which significantly increases fluid control sensitivity between adjustments

- Unlike the majority of coilovers on the market, we do not determine our adjustment range by "number of clicks" but rather, how much bleed is used i.e 4mm bleed = minimum Rebound Force. 0mm bleed = maximum Rebound Force. Typically, it takes at least 0.5mm of bleed to "feel the difference" between adjustments

- 44mm OD Forged 7075-T6 Hard Anodised Aluminium Double-Digressive Piston - Our Double-Digressive Piston is over-engineered for superior strength, with anti-stiction and anti-friction properties

- At lower shock speeds (Cornering), our Double-Digressive Piston maintains a higher damping force, offering increased responsiveness and stability

- At higher shock speeds (Bumps), our Double-Digressive Piston maintains a lower damping force, offering increased comfort and control

- Sandvik 20C Carbon Steel Shims - Only the finest Swedish Sandvik 20C Carbon Steel Shims are used, which are specifically designed for use in shock absorber valving

- Offers superior fatigue strength over the cheaper Taiwanese spring steel shims which lose their elasticity after only 12 months of normal use

- Offers superior surface finish and dimensional tolerances, increasing fluid control sensitivity and smoothness

- Although 10 times the cost of the cheaper Taiwanese spring steel shims, these premium shims ensure the consistency of our valving over extended periods

- Viton Performance O-Rings - Upgraded O-Rings offering better performance and durability than lesser-quality Rubber O-Rings

- Nitrogen Pressure Schrader Valve - Allows convenient loss-free fine-tuning of Nitrogen Pressure

- Gone are the days of using a Nitrogen Needle + Self-Healing Rubber, which are prone to leaking

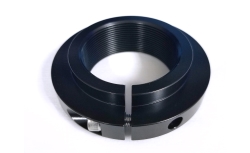

- Fully-Threaded Forged 6061-T6 Hard Anodised or High-Tensile Carbon Steel Lower Mount - Threaded Lower Mounts allow you to precisely set the amount of required bump travel according to your vehicle modifications

- Ride Height is not adjusted by the lower mount; it is adjusted by the spring perch